What is The Rice Polisher and What It’s Using

With the improvement of people's living standards and the requirements for the dietary structure. Rice is one of the main food, so the quality requirements for rice are getting higher and higher. The rice polishers as one of the important machinery of the rice processing plant, which is more and more widely used.

As we know, Rice polishers have 2 types, one is a common rice mill polisher, other one is a mist rice polisher. today we will talk about the mist rice polishing machine.

The mist rice polishing machine is used to remove the floating bran on the surface of the rice and also plays the role of pre-gelatinization and gelatinization of the surface of the rice. The starch gelatinization makes up for cracks, so as to obtain a bright and clean appearance and improve the storage performance and commercial value of rice.

It consists of a spray water part, polishing part, water supply system and air spraying mechanism, feeding device, and discharging device. The two most important parts are as follows:

Spray water part: including stirring roller, mixer, feeding screw, nozzle, nozzle cleaner, flow meter, etc, the flow meter can show how much water needs to add

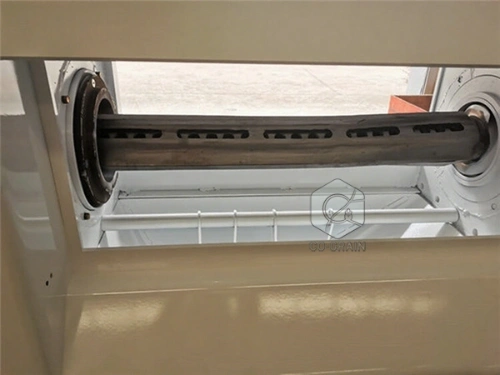

Polishing part: it is the core part of the rice mill polisher, including the polishing roller, screen, polishing delivery head, discharge pressure valve, etc.

Mist rice mill polisher working principle

The rice coming out of the rice mill is a kind of dull "white rice". Its surface is rough with floating chaff. There are countless fine powders remaining in the grooves and cavities, which are easy to flourish and not easy to preserve.

These water rice polishing machines use multiple sprays of water for polishing. The white rice enters the polishing chamber from the feed hopper through the flow adjustment mechanism. At the same time, the hot water or cold water is sprayed into the spiral conveying part according to the required proportion through the water pump part to pressurize the heater.

It has a wetting effect on the surface of white rice. After wetting, the white rice spirals along the surface of the bright alloy iron roller polishing drum. Starch forms a gum layer. Under the action of the high-pressure airflow generated by the fan, the bran powder on the surface of the white rice is forced to separate from the rice grains through the hole on the main shaft into the polishing chamber, and discharged out of the sieve hole, so that the surface of the rice is crystal clear, smooth and clean.

Advantages of Mist Rice Polishers

The rice polishers improve the grade and commercial value of the rice. The colloidal layer can also improve the antioxidant capacity of rice and extend its shelf life of rice. At the same time, the crystal clear, smooth, and clean rice surface can achieve no panning, ensuring that the rice loses fewer nutrients, and the taste is soft and delicious, which improves the rice's edible quality.

This machine can be used in conjunction with the rice milling unit, and can also be used for rice deep processing.

This water mist rice polishing machine has a compact structure, high-cost performance, and is suitable for grain enterprises. The equipment is beautiful in appearance, simple and generous, and is a good assistant for small and medium-sized enterprises.

This equipment is used for polishing white rice in the rice milling process to further improve the precision and smoothness of white rice. It is a key piece of equipment for producing high-quality polished rice. Reasonable technology, stable operation, simple operation, and convenient maintenance.

How to add water to the polisher machine:

The operating procedures are as follows:

1. After checking that the rice polishing machine, fan, and water landing parts are normal, start it in the following order:

(1) Turn on the power supply;

(2) Start the fan;

(3) Start the polishing machine;

(4) After the polishing machine is running normally, gradually turn on the flow control panel, and Adjust the rice output pressure door of the flow control board according to the output, quality, and current of the rice output;

2. Start watering: water temperature and water volume can be adjusted. The polishing room has two places the cage and the hollow spindle. The hollow shaft should be filled with water faster, and the water reaction of the cage is slow.

When the cage is used to increase the amount of water, Do not act too hastily, so as not to cause excessive water and cause blockage. When rice or chaff is accompanied by rice flour or small pieces of rice skin, and there are obvious rice grooves on the surface, the amount of water should be increased appropriately.

Under normal circumstances, twisting the rice into small clusters means that the amount of water is basically appropriate. At this time, the surface of the rice is smooth and shiny. When the amount of water is too large, a cluster will be formed with a small number of rice flakes.

3. The shutdown should be carried out in the following order:

1)Stop the water;

2)Stop feeding;

3)Turn off the polishing machine after the rice in the polishing room is empty;

4) After the polishing machine, the fan can continue to run for 5 minutes before stopping the fan to ensure the polishing room is dry to reduce accumulation and prevent accumulation of water;

5)Disconnect power

Half-finished rice polishers

Finished mist rice mill polisher delivered to Nigeria Kano state

Henan Co-Grain Machinery Engineering Co., Ltd. was established in 2000. It is a professional manufacturer and exporter of rice mills, rice processing machines, rice processing plants, rice processing plants, paddy parboiling plants, etc. We can provide a unique overall layout design, customized rice mill products, and installation services for the rice mill production line according to the different needs of customers and site conditions. It combines technology, manufacturing, and sales in one.

If You Are Ready to start a Rice Milling Business, please contact us for the Rice Milling Machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now!

Welcome, Contact Us!

Henan Co-Grain Machinery Engineering Co., Ltd.

Email: info@ricemillplants.com

Whatsapp: 0086-18339828199