The 200T/D Complete Rice Processing System is a large-scale, fully automated rice processing equipment designed to meet high-volume rice production needs. The entire production line covers the complete rice processing workflow, including cleaning, dehulling, milling, polishing, sorting, grading, and packaging, ensuring a highly efficient and stable production process. It minimizes broken rice and impurities and provides a premium final product.

To further enhance the competitiveness of your rice products in the market, we also offer rice parboiling equipment to process parboiled rice. Parboiled rice improves the quality of rice, enhances its nutritional value, and increases its market acceptance and storability. Our parboiling equipment seamlessly integrates with your rice processing production line, providing a complete, integrated processing solution.

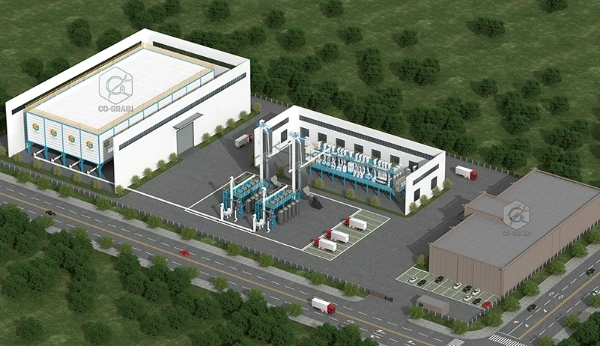

At Henan Co-Grain Machinery, the 200T/D Complete Rice Processing System we offer is not just a standalone rice milling machine, but a comprehensive solution for rice processing. As a one-stop service provider, we assist customers with everything from production equipment to plant construction, design, and after-sales support, offering professional, customized services throughout the entire process. The advantages of our one-stop service are reflected in the following key aspects:

1. Comprehensive Equipment Integration to Avoid Compatibility Issues

Customer Issue: Purchasing different brands and types of equipment separately often leads to compatibility issues, difficult commissioning, and integration problems.

Solution: We provide comprehensive rice processing equipment integration services, including milling machines, parboiling equipment, grain storage silos, and drying towers. All equipment is meticulously designed and manufactured to ensure seamless connectivity and compatibility, optimizing the production line and maximizing equipment efficiency, while avoiding any compatibility issues.

2. Customized Plant Design to Improve Production Efficiency

Customer Issue: Customers often face space wastage, inefficient workflows, or plant designs that do not meet production needs when constructing their plants.

Solution: We offer customized 3D plant design services, optimizing plant layout according to your specific needs, improving space utilization, and ensuring smooth operation of the production line. Whether building a new factory or expanding an existing facility, we tailor the most suitable design to ensure each process operates efficiently.

3. Professional Plant Construction and Infrastructure Integration

Customer Issue: Customers often encounter delays, quality issues, or budget overruns during plant construction.

Solution: In addition to providing equipment, we also assist with the construction of steel structure plants, grain storage silos, drying towers, and other essential infrastructure. Our professional team manages the entire project, ensuring timely completion, safety standards compliance, and optimal space utilization, while preventing unnecessary delays and costs during construction.

4. High-Efficiency Parboiling Equipment to Add Value to Your Products

Customer Issue: Many customers encounter issues with poorly performing parboiling equipment, which impacts the quality of the product.

Solution: Our parboiling equipment integrates perfectly with your rice processing line, enhancing the flavor, color, and nutritional value of the rice. Parboiling not only boosts the competitiveness of the rice in the market but also increases its storage stability, ensuring you produce higher-value products that meet market demands.

5. Turnkey Project Services to Simplify Management and Operations

Customer Issue: Customers often face the complexity of managing multiple suppliers and contractors, leading to extended project timelines and poor communication.

Solution: We provide comprehensive turnkey services, handling everything from project design, equipment procurement, plant construction, installation, and commissioning, to staff training. We manage the entire process, ensuring timely and quality project delivery, reducing the customer's management burden, and ensuring smooth operation of the rice processing plant.

6. Comprehensive Technical Support and Training for Long-Term Stable Operation

Customer Issue: Customers may face difficulties in operating equipment, handling faults, or maintaining consistent production line stability.

Solution: We offer comprehensive technical support and training to our customers. After equipment installation, we provide detailed training for your staff to ensure they operate the equipment efficiently. Additionally, we provide long-term after-sales support, offering solutions to any operational issues that may arise.

7. Global Experience and Localized Service

Customer Issue: Customers may face challenges related to local market demands and regulations that affect smooth project implementation.

Solution: With years of international experience, we have successfully provided rice processing solutions to multiple countries and regions. Regardless of your location, we can tailor solutions to meet local market demands and comply with regulations, while offering localized after-sales service to ensure smooth project implementation.

Whether you are just starting or looking to expand your existing rice processing business, our 200T/D Complete Rice Processing System is your ideal solution. Combined with parboiling equipment and our comprehensive one-stop services, we provide a complete, integrated rice processing system that enhances product quality, boosts market competitiveness, and improves operational efficiency.

Contact us today to learn how our customized one-stop solutions can help you establish or enhance your rice processing plant, achieving long-term success and profitability!

Let us be your solutions source.