How to Install and Adjust The 25T/D Combined Rice Milling Machine?

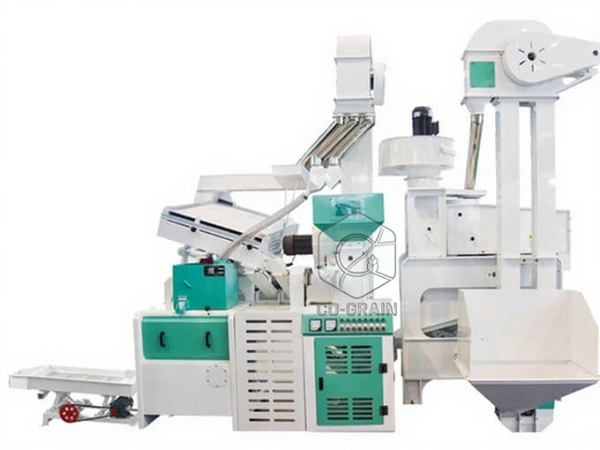

Customers who have no experience in using rice mills often face installation and debugging problems after they get the rice mill. And how to adjust the rice mill is very important to ensure its good working condition. Today, we will talk about the installation of the rice mill by taking the installation and commissioning of the 25 tons/day combined rice mill as an example.

Rice Milling Machinery Installation

Refer to the following steps when installing rice milling machinery:

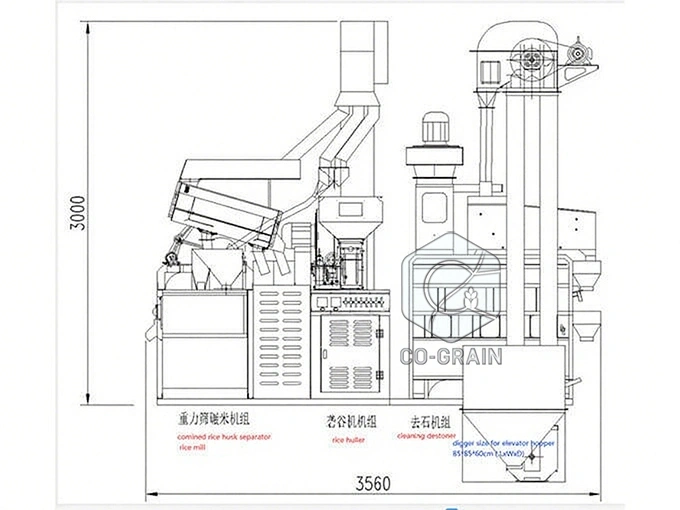

1. Choose a suitable location and dig a pit. ( pit size is 85*85*60cm)

2. Arrange the rack and fix it stably.

3. All its components are firmly installed.

4. Install all the connecting parts of the pipeline. Connect all the channels of single-machine material turnover.

5. Install all motors, V-belts, etc.

6. Connect the power supply and no-load test machine.

7. Commission the whole machine (with paddy rice)

8. after the elevator hopper pit ( size 85 length*85width*60cm depth ) is finished and an elevator installed well, then remove the base of the destoner, to fix with an expansion screw

Rice Milling Machinery Adjusting

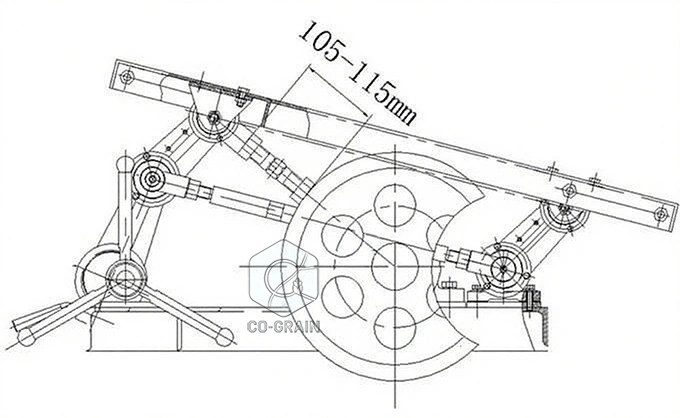

First, Control the middle adjusting screw of the gravity screen between 105-115. It depends on the coverage of brown rice on the sieve. If there are too many materials in the upper part, increase the length of the screw rod appropriately. If there is more material in the lower part of the screen surface, shorten the screw rod.

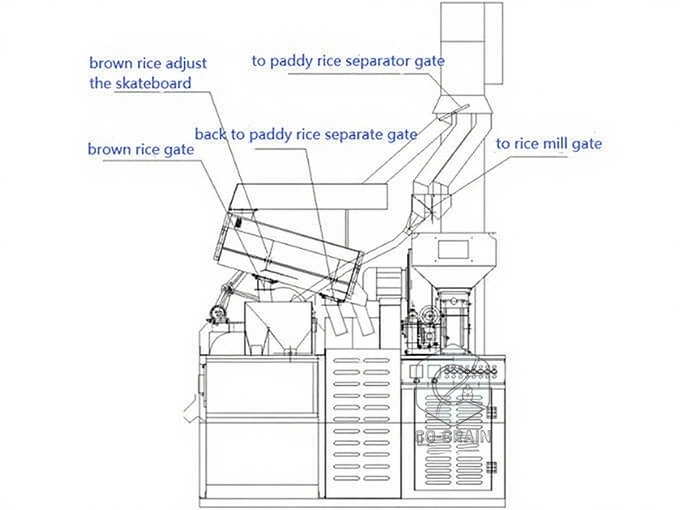

Second, When the rice milling plant is turned on, open the gate to the maximum to allow the material to enter the destoner machine quickly. Adjust the gate according to the output during processing.

Third, Before the brown rice is fed into the rice whitener, close the brown rice gate and open the return gate. Open the brown rice gate after the sieve is covered fully with brown rice.

Fourth, During processing, adjust the brown rice adjusting plate according to the condition of the brown rice on the sieve to ensure that no rice enters the rice whitener.

Fifth, Paddy rice separator operation at the end of rice mill equipment processing:

1. When the paddy going to the destoner is finished, turn off the destoner machine, otherwise, the paddy will come out of the stone mouth. At this time, look at the material in the hulling machine hopper. If there is no stock, close the return gate of the paddy separator. According to the brown rice on the sieve, adjust the brown rice adjustment board upward.

2. When the material on the sieve surface is about to end, close the brown rice gate, pull down the gate of the hoist to enter the paddy separator, let the materials flow into the hulling machine, increase the pressure of the hulling machine appropriately, and wait until the rice is peeled. Open the gate and let the material enter the rice machine from the hose for processing.

The maintenance of rice mill equipment is as follows:

First, the Destoner machine

The screen should be checked and cleaned every shift to prevent the screen holes from being blocked. The screen should be replaced in time to prevent material leakage.

Regularly remove grains and fine sand from the hood.

Second, the Rice huller machine

1. The oil filling amount in the gearbox is 0.5-0.6 kg, and it is replaced once a month.

2. When the fast roller rubber layer wears to about half, fast and slow can be used interchangeably. When the wear of the rubber roller will expose the iron core, the new rubber roller should be replaced. The two rollers should be replaced at the same time. The surface of the rubber roller should be kept flat. Find out the cause in time, repair and replace it. Pay attention to checking the parts such as drain plate, transmission gear, etc., if they are worn, they should be repaired and replaced.

Third, the Paddy rice separator

1. Check the lubricating condition of the transmission part and fill it with lubricating oil (grease) in time.

2. Overhaul disassembly and assembly sequence:

Disassembly sequence: ① material support frame, material pipe → ② discharge pipe → ③ locking angle steel → ④ traction element → ⑤ support rod mechanism → ⑥ eccentric mechanism → ⑦ motor Restore in reverse order when assembling.

Forth, the Rice mill machine

The bran suction fan impeller and air duct should be removed once every two months.

When changing the felt oil seal, it should be soaked in engine oil.

Fifth, the Common maintenance content of each machine:

1. Maintenance every 3 months and an overhaul every year.

2. Lubricating oil should be added regularly to each transmission part.

3. The bearing is usually changed once every 6 months.

4. Where the bearing is overheated, the grease is hardened, the oil color is darkened, or the oil surface has waterdrops and dirt, the grease must be replaced immediately.

When the machine is found to be violently shaken, it should be stopped immediately for inspection.

Henan Co-Grain Machinery Engineering Co., Ltd. was established in 2000. It is a professional manufacturer and exporter of rice mills, rice processing machines, rice processing plants, rice processing plants, paddy parboiling plants, etc. We can provide a unique overall layout design, customized rice mill products, and installation services for the rice mill production line according to the different needs of customers and site conditions. It combines technology, manufacturing, and sales in one.

If You Are Ready to start a Rice Milling Business, please contact us for the Rice Milling Machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now!

Welcome, Contact Us!

Henan Co-Grain Machinery Engineering Co., Ltd.

Email: info@ricemillplants.com

Whatsapp: 0086-18339828199