Custom 60T/D Rice Milling Production Line for Ugandan Customer

Our company recently completed the installation of a customized 60T/D rice milling production line for a customer in Uganda. After researching various suppliers online and comparing different rice milling solutions, the customer chose us for our expertise, innovative technology, and proven track record of delivering high-performance, tailored solutions worldwide. Here’s a closer look at the machines and features included in this comprehensive project.

Project Overview:

The 60T/D rice milling production line we provided for our Ugandan customer was designed to process 60 tons of rice per day. The complete production line includes a series of integrated machines, each tailored for specific tasks in the rice milling process. The fully automated system ensures efficiency, consistency, and high-quality output, while customizations were made to optimize the layout and operation.

Key Machines and Features in the 60T/D Rice Milling Line:

Rice Cleaning Machine

Function: Removes dust, dirt, stones, and other foreign materials from raw rice.

Details: This machine uses a combination of sieves and aspiration (air separation) systems to thoroughly clean the rice. The cleaning process is essential for ensuring that the raw paddy is free from impurities that could damage other machines in the production line.

Benefits: Improved rice quality, reduction in wear and tear on downstream equipment, and enhanced overall product consistency.

Stone Removal Machine

Function: Separates stones from the rice to prevent damage to milling equipment.

Details: This machine utilizes a high-efficiency stone separator, which uses gravity and vibration to remove even small stones and heavier debris from the rice before milling begins.

Benefits: Ensures that rice is completely free of stones, preventing damage to the husking and milling machines, and reducing maintenance needs.

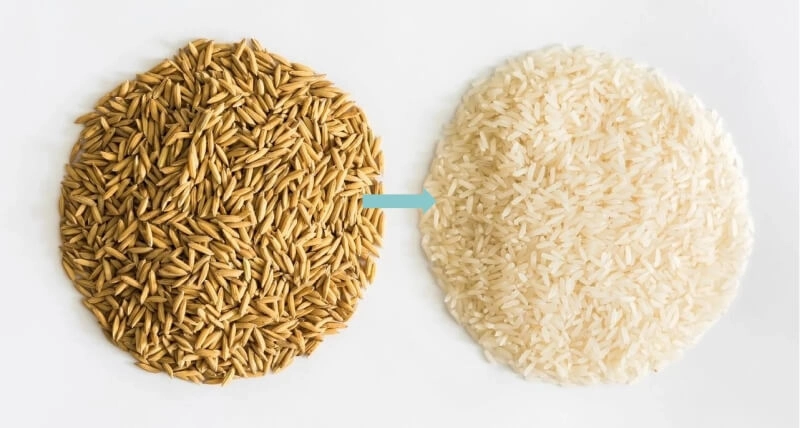

Husking Machine

Function: Removes the husk from the rice, separating the brown rice from the husk.

Details: This high-performance husker is designed to handle large volumes of rice while maintaining a low percentage of broken kernels. It uses rubber rollers to gently remove the husk without damaging the grain inside.

Benefits: High husking efficiency with minimal breakage, maximizing yield and quality.

Rice Milling Machine (Whitener)

Function: Removes the bran layer from the brown rice, producing white rice.

Details: Our rice milling machines use abrasive polishing and friction to remove the bran while preserving the integrity of the rice kernel. The whitener is equipped with multiple adjustable settings to allow for fine-tuning based on the raw rice quality and desired outcome.

Benefits: Ensures high milling efficiency and white rice with minimal broken kernels.

Rice Polishing Machine

Function: Polishes the rice to improve its appearance and make it shinier.

Details: The rice is polished using a combination of abrasive pads and gentle friction, resulting in a smooth, polished finish. This not only enhances the appearance of the rice but also removes any remaining bran or impurities from the surface.

Benefits: Polished rice with a high-quality finish, improving the product's marketability.

Rice Color Sorter

Function: Sort rice based on color, removing any discolored or defective grains.

Details: The optical sorting machine uses advanced cameras and sensors to detect and remove defective rice, ensuring uniformity and a high-quality end product. The machine operates at high speed, capable of processing large quantities of rice efficiently.

Benefits: Consistent product quality and uniformity, ensuring that only the best rice reaches the market.

Rice Grading Machine

Function: Sorts rice by size to separate different grades.

Details: The grading machine uses a series of sieves with varying mesh sizes to sort rice into different grades based on size and shape. This ensures that each grade of rice is packed separately, meeting specific market requirements.

Benefits: Efficient sorting and grading, leading to higher-quality product offerings and better market segmentation.

Rice Packaging System

Function: Automatically packs the rice into bags for sale.

Details: The packaging machine is equipped with an automatic weighing and bagging system that can handle packaging sizes from 5 kg to 50 kg. The system is designed for high-speed packaging, reducing manual labor and improving packaging efficiency.

Features: Automatic sealing and labeling are also included to ensure each package is properly sealed and correctly labeled for retail sale.

Benefits: High packaging accuracy, improved efficiency, and flexibility to meet different market demands, from bulk sales to retail packaging.

Custom Steel Platform and Maintenance Platform:

Understanding the specific factory layout requirements of our Ugandan customer, we customized a steel platform to house the entire rice milling production line. This platform was built to accommodate the height of the customer’s factory and support the various machines efficiently.

Steel Frame Platform: Optimized for easy access to the machines and providing ample space for smooth operations.

Maintenance Platform: Designed for convenient access to key components of the production line, this maintenance platform ensures that servicing can be carried out without causing significant downtime.

Fully Automated Control System:

The entire rice milling line is operated through an automated control system via a centralized control panel. This panel integrates all the machinery, allowing for seamless operation from the cleaning stage through to packaging.

PLC Integration: The production line is controlled via Programmable Logic Controllers (PLC), which automate tasks such as speed regulation, material flow, and batch control. This ensures consistent quality and reduces human error.

Remote Monitoring: Operators can easily monitor the status of each machine, receive alerts for any issues, and adjust settings to optimize performance.

Why Choose Our Rice Milling Solutions:

Tailored Solutions for Every Need: Whether expanding an existing facility or starting a new rice milling business, we offer custom solutions to your specific production goals.

Advanced 3D Design Capabilities: We provide 3D renderings of the entire rice milling line, ensuring the layout is optimized for space and efficiency before installation begins.

Global Expertise: With successful projects completed worldwide, including in Africa, Asia, and beyond, we have the experience to handle any project—big or small. Our customers choose us because we deliver results that improve their production and bottom line.

Contact Us for Your Custom Rice Milling Solution

If you’re looking to expand your rice milling operation or start a new project, our team is ready to provide you with a customized, high-performance solution that meets your production needs. From project design and machine selection to installation and after-sales service, we’re committed to supporting you every step of the way.

Contact us today to discuss your specific needs, and let us show you how our expertise and global experience can help you succeed in the rice milling industry.

Henan Co-Grain Machinery Engineering Co., Ltd. was established in 2000. It is a professional manufacturer and exporter of rice mills, rice processing machines, rice processing plants, rice processing equipment, paddy parboiling plants, etc. We can provide a unique overall layout design, customized rice mill products, and installation services for the rice mill production line according to the different needs of customers and site conditions. It combines technology, manufacturing, and sales in one.

If you are ready to start a rice milling business, please contact us for information on the rice milling machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now!

Welcome, Contact Us!

Henan Co-Grain Machinery Engineering Co., Ltd.

Email: info@ricemillplants.com

Whatsapp: 0086-18339828199