Our 40T per batch parboiling rice equipment and 60T per day rice milling equipment are designed to provide a highly efficient and integrated rice processing production line. As a leading supplier of rice processing machinery, we offer comprehensive one-stop services, covering everything from project planning, equipment design, and production line construction to installation, commissioning, and ongoing support. This ensures that your rice processing project is smoothly launched and operates efficiently from start to finish.

Our parboiling rice equipment and rice milling machines offer a fully automated production line, ideal for large-scale paddy processing and rice production.

1. 40T Per Batch Parboiling Rice Equipment:

Utilizing advanced parboiling technology, this equipment treats paddy rice with high-temperature steam, enhancing the nutritional value and flavor of the rice. The steaming process is precisely controlled for temperature and time to ensure that the rice maintains optimal color, texture, and nutrition. The equipment supports efficient soaking, steaming, drying, and cooling, and can be customized to produce various rice colors based on customer needs.

2. 60T Per Day Rice Milling Equipment:

Our rice milling machinery uses state-of-the-art whitening technology to process paddy into high-quality white rice. This equipment minimizes breakage, reduces milling temperature, and lowers bran content, ensuring the integrity of the rice grains and reducing broken rice. With advanced automatic control systems, the entire production process is streamlined, resulting in improved efficiency and product quality.

3. Efficient Drying and Cooling Systems:

The integrated drying tower and cooling systems ensure that paddy is processed to achieve the ideal moisture content before milling. This step improves the milling efficiency and the overall yield of whole grains while reducing the potential for cracks and breakage in the rice.

4. Fully Automated Production Line:

The entire production process, from raw material cleaning to packaging and grading, is fully automated. Our intelligent control system allows for real-time monitoring, optimizing production efficiency, and reducing operational costs and maintenance.

As a comprehensive rice processing equipment provider, we not only supply high-quality machinery but also offer a complete one-stop solution, ensuring a seamless experience from project initiation to full-scale operation. Our services cover everything from planning and design to installation, commissioning, and post-production support, providing you with peace of mind throughout the entire process.

1. Comprehensive Project Planning and Design:

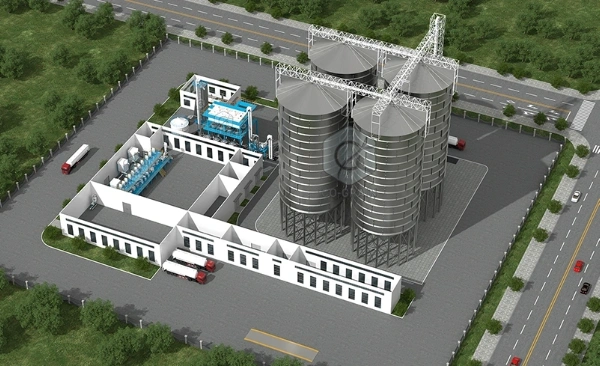

We offer customized plant planning and design based on your production capacity and site conditions. Our engineers will work closely with you to design the most efficient layout for your production line, using 3D modeling and optimized space planning to maximize space utilization and operational efficiency.

2. Turnkey Engineering Solutions:

As specialists in turnkey projects, we manage every step of the process, from initial consultation to equipment procurement, plant construction, installation, and commissioning. Our project managers will ensure that your project is completed on time and meets your specifications, allowing you to focus on your core business while we handle the rest.

3. Plant Construction and Steel Silos:

We provide plant construction services, including structural design and installation. Additionally, our steel silo solutions are ideal for storing paddy rice, maintaining its freshness, and preventing contamination. The steel silos can be customized to meet the specific needs of your production scale and storage requirements.

4. Drying Tower and Full-Scale Drying Solutions:

Our drying towers are designed for efficient drying of paddy rice, using optimized temperature and humidity control to ensure the rice achieves the ideal moisture content for milling. This system helps reduce breakage rates and ensures uniform drying, improving the overall yield and quality of the rice.

5. Installation, Commissioning, and Training:

We don’t just deliver equipment; we also provide installation and commissioning services, ensuring that your rice processing line is running smoothly from day one. Additionally, we offer professional training for your operators, ensuring they are well-versed in all aspects of the production process, equipment operation, and troubleshooting.

6. Ongoing After-Sales Support and Maintenance:

Our commitment to customer satisfaction extends beyond installation. We offer comprehensive after-sales support, including regular maintenance, technical assistance, and spare parts supply, to ensure the continued smooth operation of your rice processing line. Our technical team will regularly inspect and optimize your equipment to ensure peak performance throughout its lifespan.

Extensive Industry Experience: With years of experience in the rice processing industry, we have successfully delivered hundreds of custom solutions worldwide, ensuring high-quality products and services.

State-of-the-Art Equipment: Our machinery is built with the latest technology, offering high efficiency, energy savings, and minimal maintenance, ensuring long-term reliability.

Global Reach: We provide expert installation, commissioning, and ongoing technical support worldwide, ensuring the highest level of service no matter your location.

Tailored Solutions: Our engineering team offers fully customized solutions that meet your specific needs, whether you are building a new rice mill or upgrading an existing one.

Whether you are setting up a brand-new rice processing plant or optimizing an existing production line, we offer a comprehensive solution to meet all your needs. From plant design to installation, and from equipment supply to automation, we are your trusted partner in achieving efficient and profitable rice processing operations.

Contact us today to learn more about our 40T parboiling rice equipment and 60T rice milling machinery, and discover how our customized one-stop solutions can optimize your rice processing business.

Let us be your solutions source.