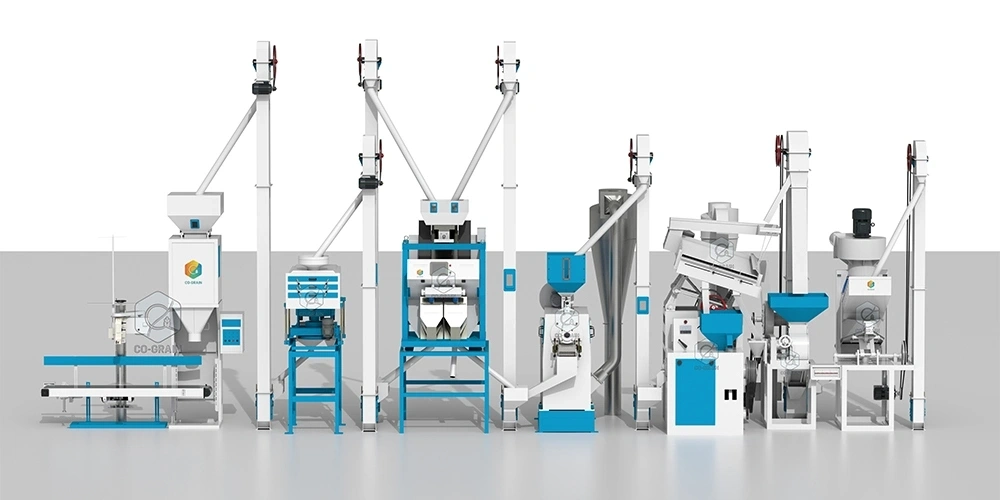

Our 15T/D Complete Rice Mill Plant is designed to meet the needs of small to medium-sized rice milling businesses, offering an efficient and fully automated solution for turning raw paddy into high-quality white rice. The system includes all essential stages of rice processing: paddy cleaning, de-stoning, husking, brown rice separation, milling, grading, polishing, color sorting, and final packaging. This plant operates smoothly with minimal labor, making it an ideal choice for farms, small towns, schools, and rice milling factories.

At our company, we believe in offering a complete solution for rice processing, from start to finish. In addition to the 15T/D rice mill plant, we also provide parboiled rice processing systems, 3D layout design services, grain silos, and rice dryers—all tailored to meet your specific needs. Whether you're looking for a traditional rice milling plant or a more specialized system like a parboiled rice mill, we are your one-stop supplier.

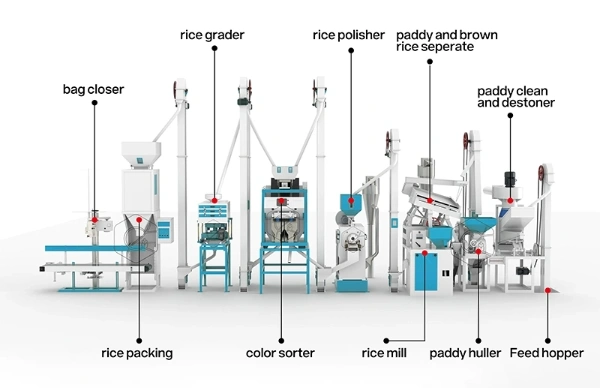

Paddy Cleaner & Destoner: Removes dust, debris, stones, and other impurities from the raw paddy, ensuring a cleaner input material.

Rice Husk Removal: Efficiently removes the husk from the paddy using a rubber roller rice husker for a high husk removal rate.

Brown Rice Separator: Separates brown rice from paddy using specific gravity and friction coefficient differences.

Rice Whitening: Advanced rice milling technology produces high-quality white rice with minimal broken rice and reduced bran content.

Rice Polisher: Enhances rice gloss by polishing the surface with water, improving storage and extending shelf life.

Rice Grader: Accurately sorts milled rice into different categories such as head rice and broken rice.

Rice Color Sorter: Removes discolored, unqualified rice, and foreign materials using advanced CCD technology.

Packaging System: Includes an automatic packing scale that can handle bags from 1-50kg for ease of market distribution.

3D Design: We provide 3D layout design services to optimize the placement of equipment and streamline the production process, helping you maximize space and workflow efficiency.

Steel Silos for Storage: We offer durable steel silos for storing raw paddy and finished rice. These silos help maintain the quality of your rice and allow for bulk storage, ensuring you always have a steady supply.

Rice Dryers: For those looking to process parboiled rice, we provide high-performance rice dryers to ensure your paddy is perfectly dried, preventing spoilage and improving milling quality.

Comprehensive Solutions: From rice milling and parboiling to storage and drying, we provide everything you need to set up a complete rice processing plant. Our one-stop approach saves you time, reduces complexity, and ensures consistent quality.

Tailored to Your Needs: Every plant we design is customized to your specific requirements, including the plant’s capacity, factory layout, and optional equipment.

Global Experience: With years of experience and successful projects worldwide, we understand the intricacies of rice milling and provide solutions that meet global standards.

Ongoing Support: We don’t just stop at installation—we provide continuous support and training to ensure your equipment operates smoothly for years to come.

Let us be your solutions source.